AGGREGATE HEATING

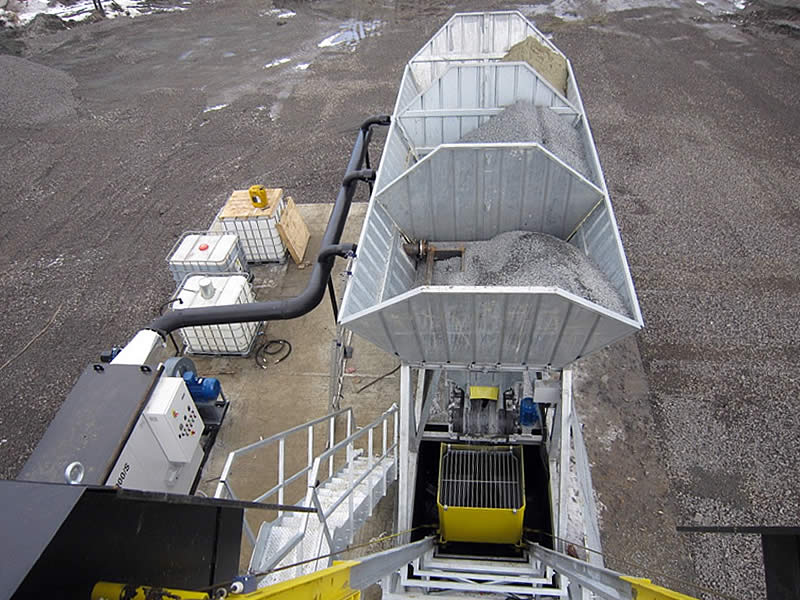

When harsh winter conditions affect batching plants productivity, Ione has the right answer to the problem with SIMUN series hot air generator.

Traditionally, producers have employed live steam directly injected inside the aggregate bins, but, due to the drawbacks of live steam injection method, hot air generators have replaced steam boilers. Forced hot air blown into the aggregate bins allows producers to defrost and raise the aggregate temperature.

FEATURES:

Even available in container package ready for plug-play.